URGO Laboratoires choose SEA Vision as a partner to support them with the implementation of a control system for their Medical Device. To date, 10 lines of a first site have already been equipped. The objective of URGO Laboratoires is to continue the deployment at the rate of 1 line per month.

Pavia, September 05th, 2022 – The new European regulation 2017/745, which entered into force on May 26, 2020, reinforces the obligations of traceability and transparency of the medical device (MD) supply chain. A unique identification system will have to appear on the DM in two formats: an AIDC format (linear code, 2D code, RFID) and human-readable characters format.

The following data will be printed at least on the product: the Device Identifier (DI) and a Production Identifier (PI that consists of a batch number, expiry date, manufacturing date, etc. The software of all operators must be able to read and record electronically the related information to ensure the traceability of MDs throughout the distribution chain and, for certain products, up to the patient.

This issue is therefore fundamental for the manufacturers, who are responsible for setting up the system according to an already fixed schedule.

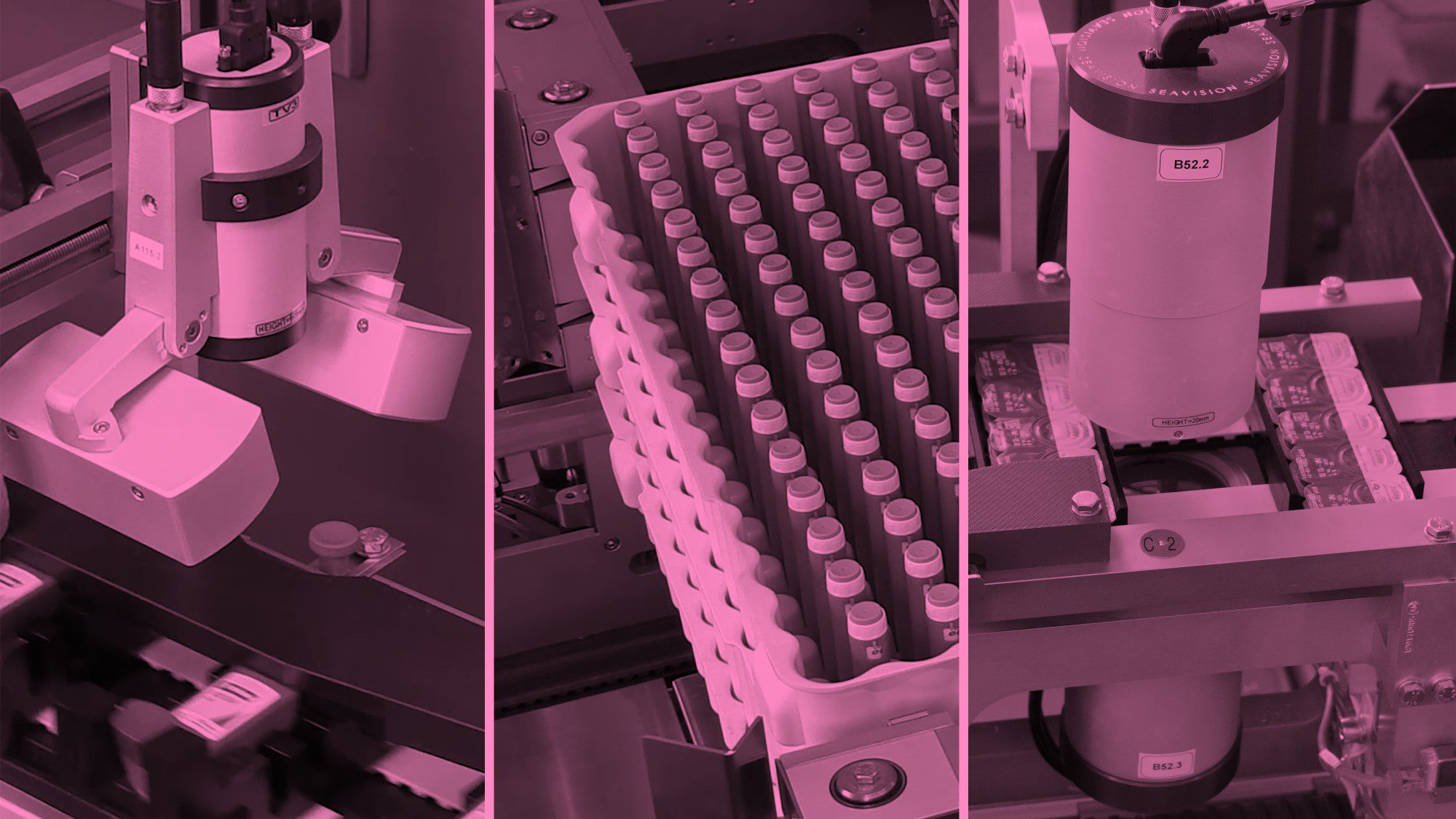

A unique control device

For this large-scale project, URGO Laboratoires choose SEA Vision as a partner to support them with the implementation of a control system. SEA Vision’s expertise in the field of image acquisition and the flexibility of the proposed solution guaranteed to answer the patches and cartons specifications of the lines UrgoStart, UrgoTul, Silver range, Sanyrene and Traditional wound care.

The main challenge was to avoid false rejections of non-reprocessable products, in order to reduce the associated financial losses as much as possible. This challenge assumes the implementation of an optimal marking for perfect repeatability but also an optimized control system (luminosity and resolution of the vision system). The solution, installed by SEA Vision, is based primarily on a lighting system designed to allow reliable control of products with reflections despite the interference inherent in outdoor lighting.

To simplify the control then, the printing device selected and installed by URGO is directly and fully controlled by the control system, which controls also the creation of the masks and the communication of the data to be printed. The line is thus equipped with just one user-friendly interface.

The ANSI grade verification of the code is made in-line, and it is carried out by an algorithm emulating the ISO15415 standard, which makes it possible to control the printing quality on 100% of the printed codes (rate of 3 to 4 products/sec). This guarantees the minimum grade required by the regulations.

The recovery of data stored in the ERP of URGO Laboratoires is carried out by an interfaced middleware. In this way, when launching a batch, the operator only need to select the production order from a drop-down menu. The absence of data entry eliminates the risk of error and guarantees the printing of exact data (data integrity). The system is fully automated for an optimized functioning.

The first installation in November 2021 has made it possible to make the necessary corrections to the recipe. To date, 10 lines of a first site have already been equipped. The objective of URGO Laboratoires is to continue the deployment at the rate of 1 lsine per month.

The extreme flexibility of the device installed by SEA Vision opens the possibility of an extension to many other products impacted by the new regulatory directives, as well as that of a possible outsourcing.

The culture of technological innovation is at the service of the pharmaceutical industry.

With 25 years of expertise in the design and development of software and vision systems specifically dedicated to the pharmaceutical industry and continuous investment in R&D, SEA Vision offers the most innovative technological solutions (EU/UL/CAS certified) to solve even the projects with the highest levels of complexity.

For more info:

Press Officer SEA Vision:

Antonio Leggieri

[email protected]

Company contact:

Maria Grazia Preda

[email protected]

+39.392.1771730