Cosmopack 2024: Artificial Intelligence-based software solutions for lipstick inspection and cosmetic products verification

Pavia, 15th February 2024 – The 55th edition of Cosmopack – the world’s most important trade show dedicated to the cosmetics supply chain and part of Cosmoprof Worldwide – is back from March 21st to 23rd, 2024.

SEA Vision will present its latest innovations at Hall 19PK – Stand A/9PK (Stand Marchesini Group). Among these is the a-eye lipstick vision system developed by SEA Vision and ARGO Vision, which recently won the award for the “innovative technologies” category at the Cosmopack Asia awards in Hong Kong and will be showcased at Cosmopack for the first time installed in combination with an automatic Lipstick moulding machine Cosmatic SM 2000.

Moreover, the end-to-end traceability solution dedicated to the beauty world for fighting the grey market will be showcased at the booth. By scanning a code on the lipstick case, it will be possible to verify the authenticity of the product and explore other information made accessible by the solution depending on the type of user.

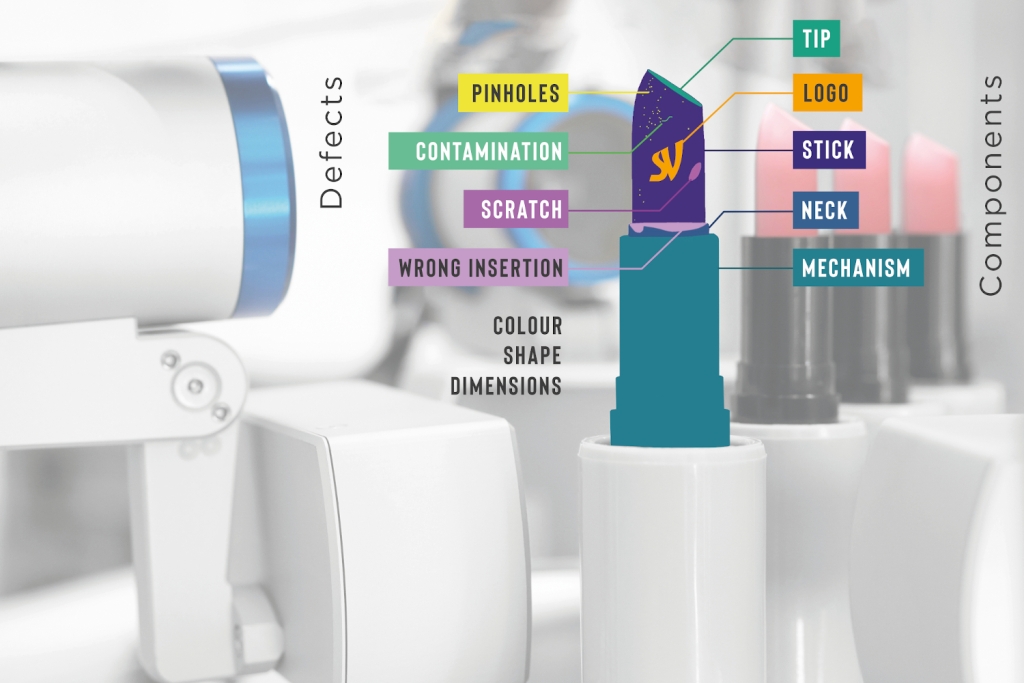

a-eye lipstick in action on an automatic lipstick machine

a-Eye Lipstick, recently awarded as the best innovation at the Cosmopack Asia trade fair (held in Hong Kong last November), is the world’s first system for the automatic control of lipsticks during production based on Artificial Intelligence techniques. It automates the quality inspection process of lipsticks, previously largely entrusted to manual human control.

The core concept behind a-eye lipstick is to solve a problem: the wide variety of features that distinguish lipsticks (colors, finishes, shapes, formulations, and combinations) makes the inspection process an extremely complex task when carried out with the use of automated inspection with classical machine vision systems.

The system is based on proprietary algorithms driven by Artificial Intelligence: the use of innovative neural, pre-neural and non-neural technologies enables the ideal balance between inspection quality and efficiency during the production process.

The system features cutting-edge hardware which is easy to integrate and revolutionizes the way quality control can be performed on 100% of the products and with no impact on production timings.

By means of 360° lipstick image acquisition, the system identifies every possible imperfection, ensuring a flawless final product. This is an essential factor in an industry where precision and excellence are crucial for the brand’s reputation.

The A-Eye Lipstick solution represents a significant step forward in lipstick quality controls, ensuring the utmost precision in evaluating the quality of these products across the whole production process.

Cosmetics authenticity verification: an end-to-end solution to fight the grey market.

The nature of the cosmetic sector is dynamic, just like its consumers. Recent research indicates a shift in people’s purchasing habits that, compared to the past, are increasingly influenced by new trends.

The research on product safety, the attention for the use of natural ingredients, sustainability, and waste disposal sustainability are increasingly catching the attention of consumers and leading to further product differentiation.

Thanks to innovation and technological advancements, today the beauty industry can introduce products to the market that provide customers with significant and verifiable data. With more than 20 years of experience in the traceability sector, SEA Vision has developed an end-to-end cosmetic solution that will be showcased at the upcoming edition of Cosmopack 2024. With a flexible architecture enabling manufacturers to digitalize product information, this solution offers complete visibility of the distribution chain and maximizes the possibility to exploit the collected data.

Ensuring products authenticity has become crucial in the cosmetic industry to protect the reputation and image of manufacturing companies in the fight against the grey market or parallel importation. The solution developed by SEA Vision covers all the phases of the products manufacturing and distribution processes (from serialization and aggregation during the packaging process, to warehouse management, up to the final phase of distribution and sales to consumers) and it has the objective of tracking the products with the aim of identifying their authenticity and origin. The solution is composed by:

– a software, yutrace, that collects and stores in a database all the production and serialization data at production site level;

– systems for vision inspection and serialization on packaging lines for the application of a unique identifier that transforms products from real to digital. The software manages the full cycle of printing of QR codes/ Datamatrix/ 1D codes/ RFID/NFC tags and their subsequent control. The unique identifier is registered into the database and readable along the entire supply chain.

– applications Reworkapp and Pickapp for processes of reworking and picking in the warehouse. Reworkapp allows the performing of reworking operations. With Pickapp, instead, it is possible to fill purchase orders and shipments. The Purchase order information is stored in a dedicated database with the aim of monitoring products along the distribution chain.

Additional information can be integrated by distributors, importers, or agents, creating a dynamic experience within the supply chain. The solution is structured with different levels of access, to provide specific information based on the type of user, whether it is a consumer, manufacturer, importer, agent, or retail. All is configurable according to specific needs.

An example of a user is the customer: by scanning the digital code (e.g., QR code) on the purchased product, the customer accesses the manufacturing company webpage containing all the information about the ingredients, usage, and disposal of the product. In this way the customer can quickly find important details about the purchased product and can verify if it is original or counterfeit, thereby encouraging a more informed and ethical consumption.

The advantage for a company adopting such a solution is to establish the maximum level of trust with its final customers, ensuring products with the highest level of safety.

Fill in this form to get a discount code* for purchasing the fair ticket at a reduced price.

*The discount code is valid for registrations made up to 24th March and it allows to purchase a discounted ticket by choosing from these options:

-1 day ticket: 30€ (instead of 40€)

-2 days ticket: 48€ (instead of 65€)

-3-5 days ticket: 78€ (instead of 105€)