The growth in the cosmetics market has gone hand-in-hand with an increase in counterfeiting, causing side-effects on cosmetic companies, such as: loss of profits, brand reputation under attack, compromised long-term trust, not to mention the serious damage caused to consumer health. In this context it is very clear why many companies are asking instruments to actively fight counterfeiting to protect their brands. End-to- end Serialization solution provided by SEA Vision is the way to answer to these needs.

From the long experience in the field of pharmaceutical anti-counterfeiting solutions, SEA Vision has created a set of complete solutions for beauty products serialization, putting all their traceability skills at the service of cosmetic sector.

All these solutions will be on show from 26th April to 6th May 2022, at the Open House Beauty and Open Door Pharma events by Marchesini Group.

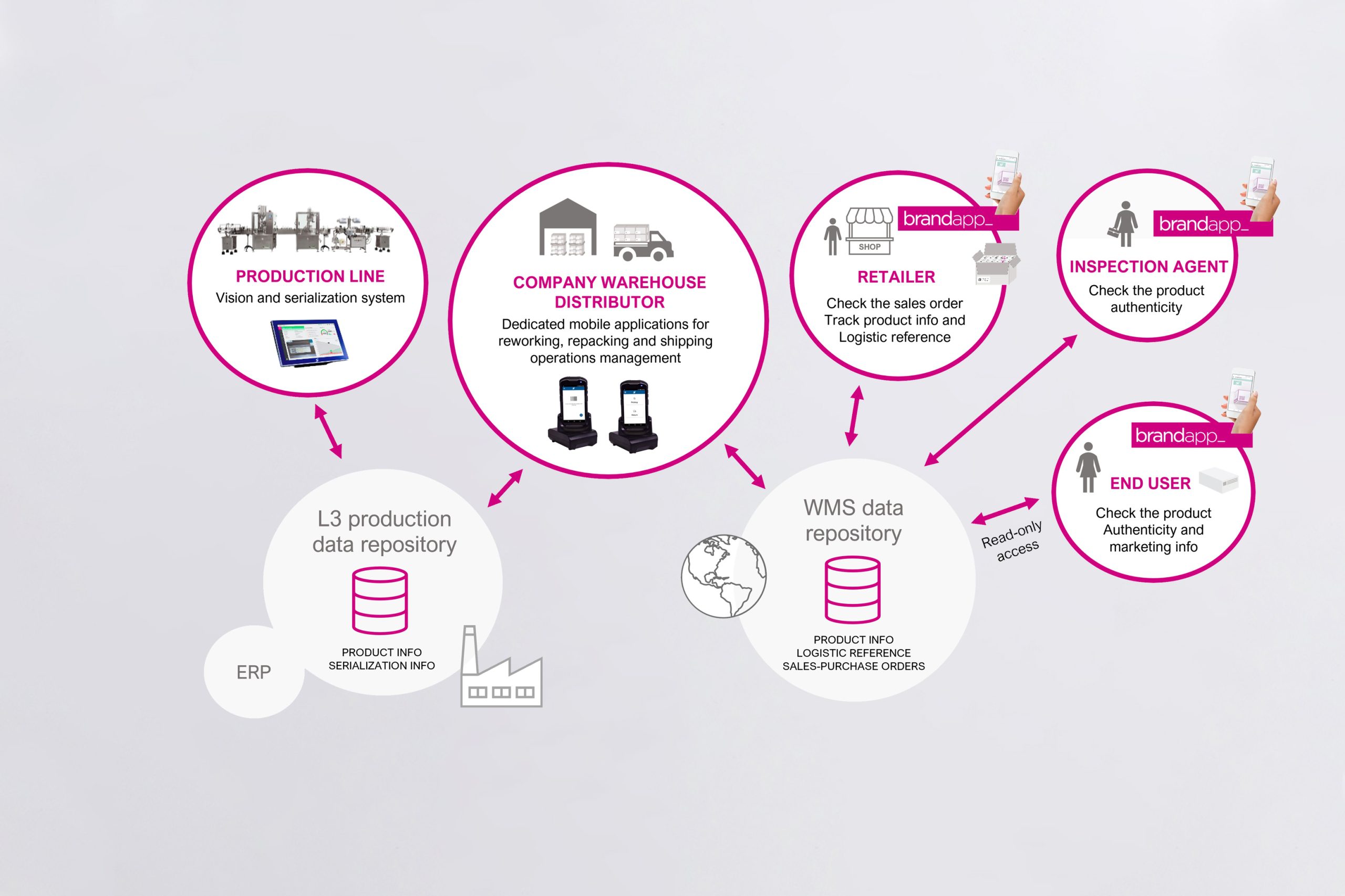

SEA Vision end-to-end solutions cover all the steps of beauty product distribution, including their packaging serialization and aggregation, warehouse and supply chain operation, and the final phase of commercialization and delivery to the consumers.

SEA Vision serialization system on labelling machine

Installed on the carton labelling machine SLA210, the system for cosmetics serialization provided by SEA Vision manages the entire cycle of serial numbers marking and verification performed during the packaging processes on the labelling machine, and communicates with yudge and yutrace, respectively the L4 and L3 systems for Serial number Generation and management.

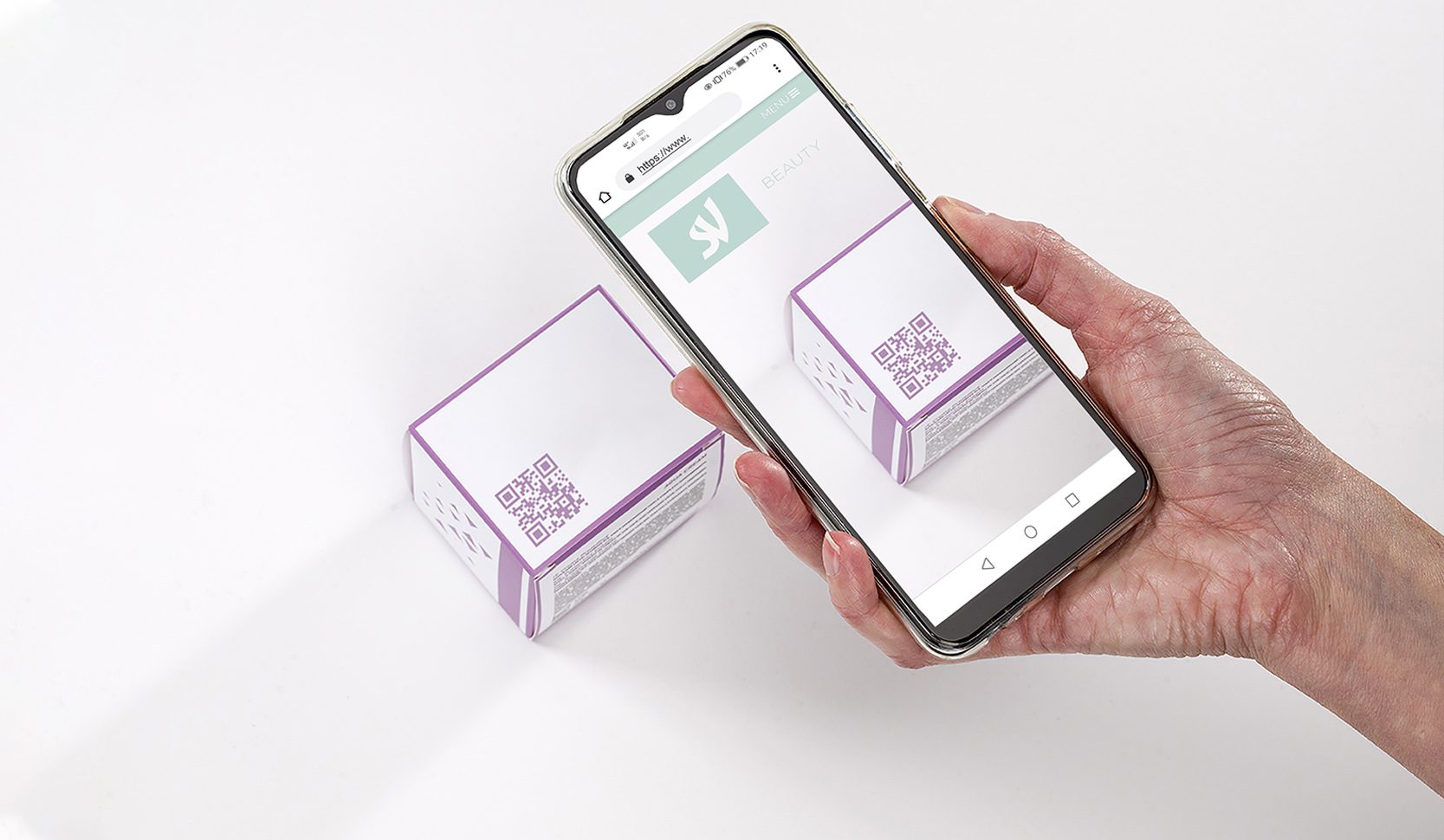

Cosmetics selling units are marked with a pack-specific unique identifier accordingly to GS1® standards (2D QR code), which are autogenerated from SEA Vision software or taken from a third-party system and stored in a protected database for tracing along the subsequent supply chain.

A workstation with a system for aggregation: Trackscan

The next step is the products aggregation: at the Open House Beauty SEA Vision will show Trackscan, a handy and lightweight workstation with integrated vision system that allows the commissioning of cases, and aggregation between good cartons coming out from the labelling machine and cases, up to pallet level – thus enhancing products traceability in the supply chain.

Warehouse and supply chain solutions: Pickapp and Reworkingmobile

The range of solutions provided cover the warehouse operations too and include Reworkapp and Pickapp.

Reworkapp is the mobile solution for warehouse, to deal faster and in full mobility with reworking operations on serialized/aggregated batches, post-packaging reworking and shipment operations.

Pickapp is a mobile warehouse solution designed to automate the shipping process of the products in the warehouse and distribution centers. Installed on an industrial smartphone with an Android operating system, the software of Pickapp checks the correctness of the products picked, associating them to the relative purchase order. The great advantage of this application consists in the digitization of a workflow that is usually paper based, to increase the speed and the efficiency of the process.

Brand protection for cosmetic industry: Brandapp

At the final step of the end-to-end serialization process, visitors will have the chance to see in action the Brandapp mobile solution. It is an application capable to check the correct products distribution on sales channels as well as the authenticity of products once placed on the market. Scanning the QR code printed on the products, the users can immediately see the history of the product, recovering a set of real-time data like:

- name;

- production date;

- batch number;

- expiry date;

- other useful logistic information such as delivery date, number of the shipping order and address of the point of sale for which it is intended.

Based on SEA Vision’s great experience in traceability systems, this solution is designed for cosmetics companies that need to protect the authenticity of their brand, promote transparency, enhance quality, sustainability and actively fight counterfeating.

End-to-end solutions, natively integrated with yudoo

All the machines and systems presented at the show will be connected with yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track and Trace management.

Yudoo – a digital hub that is everywhere accessible through a secure-access web interface or dedicated devices – is a scalable and modular suite, including tools for automation (centralized management of production, workflows, and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data and reducing work time. The suite can connect to existing company systems such as ERP or MES to retrieve updated data exactly from where they are.

Other available solutions for cosmetics

The solutions of SEA Vision for the cosmetic sector are not just about traceability and distribution processes, but the range extends to the vision inspection application too.

A touch screen panel will show all the range of vision inspection applications designed for products and packaging inspection (presence, shape, colors, and so on), including the control of codes and characters. This is the historical core business of SEA Vision where the company has over 25 years of experience.

For more info:

Press Officer SEA Vision:

Antonio Leggieri

[email protected]

Company contact:

Maria Grazia Preda

[email protected]

+39.392.1771730