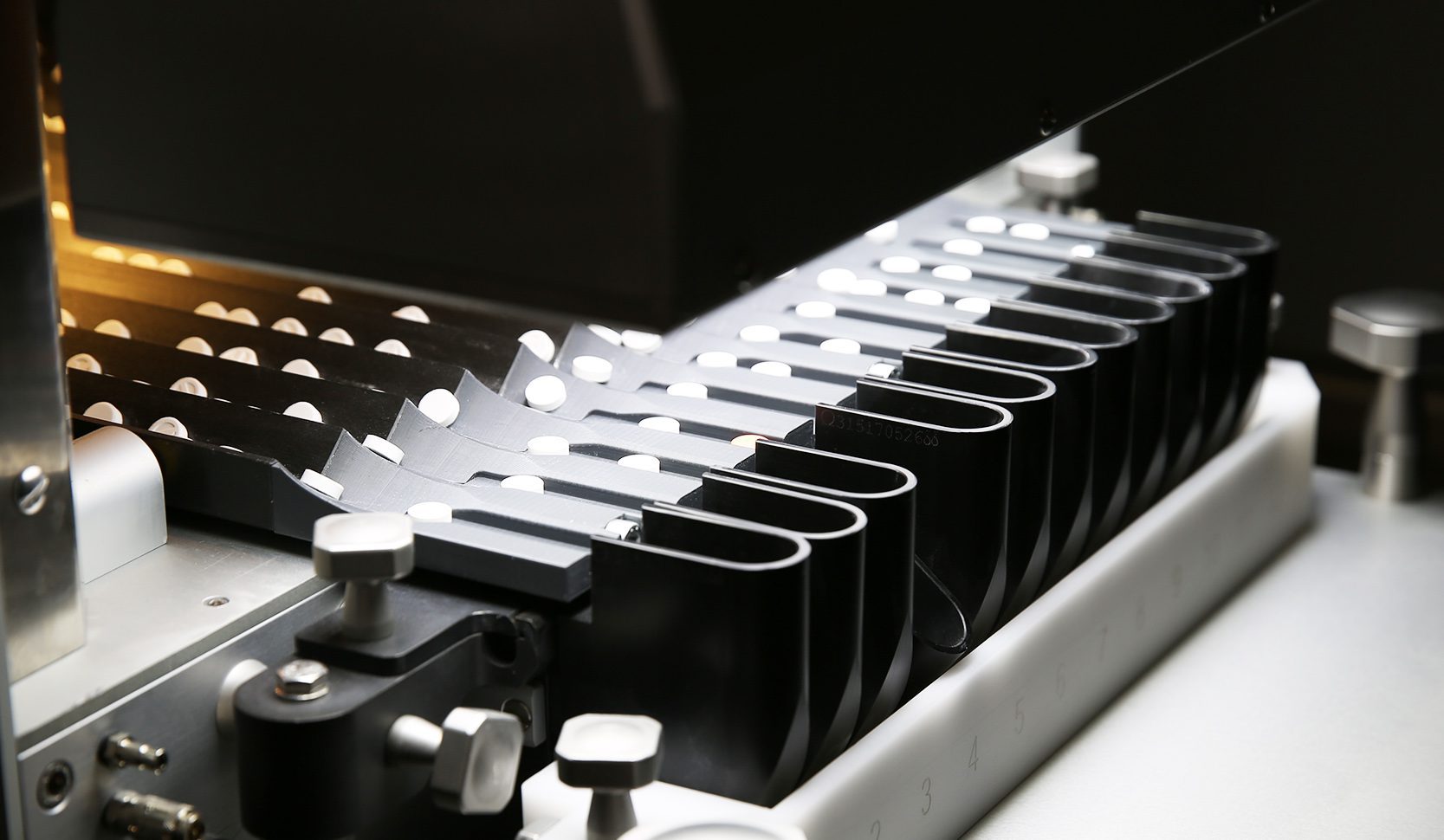

Harle2D|3D vision inspection system combines a traditional 2D vision inspection with a 3D control to ensure 100% control of the oral solids inspected on the feeding unit of counting machines, blister thermoformers or strip packaging machines before the packaging.

While Harle2D performs a traditional check of the oral solid (mainly size, shape and colour), Harle3D analyses height information to control the product thickness: in this way it is possible to find defects that would otherwise be invisible for a standard bidimensional vision system.

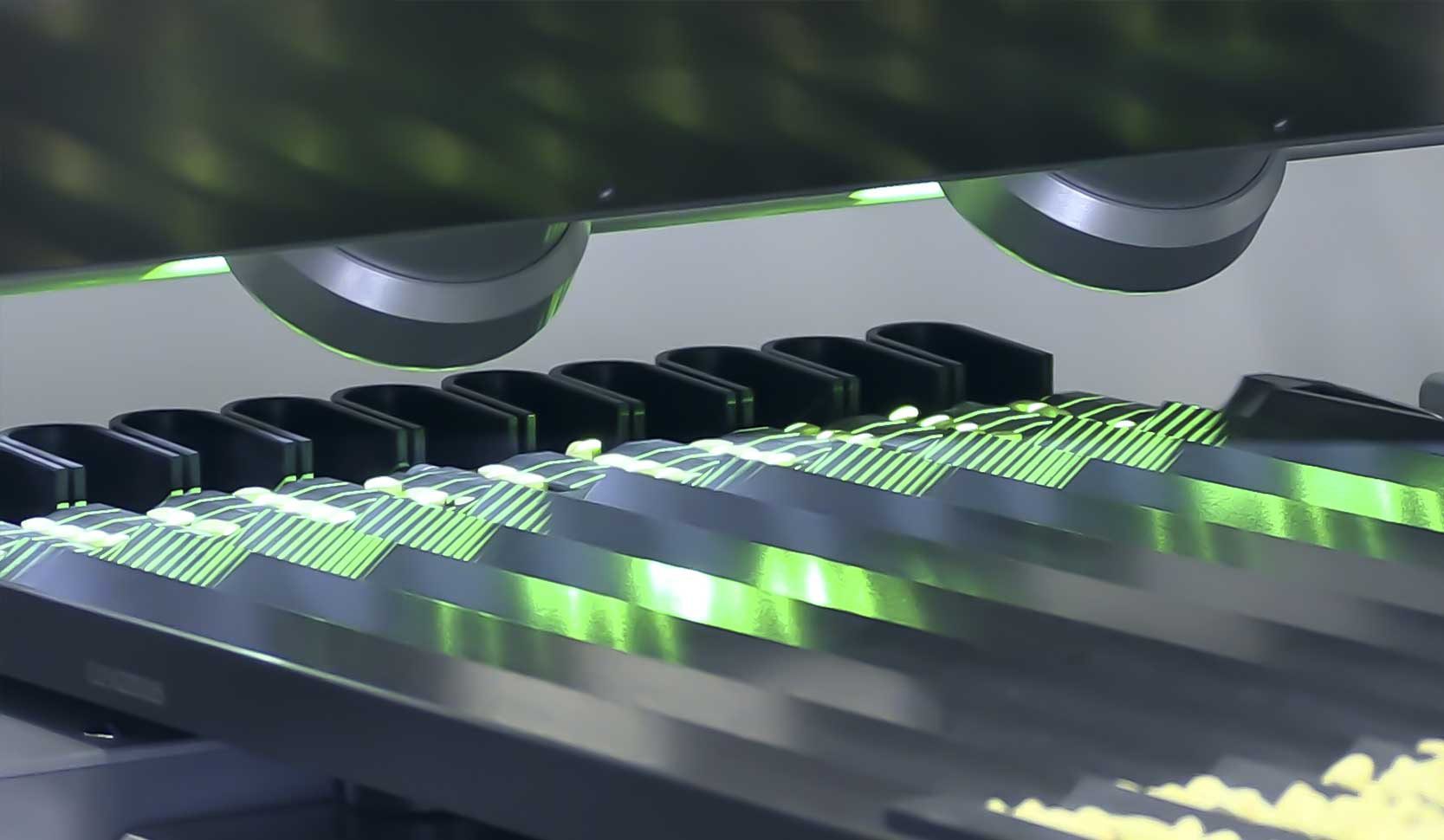

The vision system tracks every product in movement on the feeding channels and allows single wrong product rejection, preventing the outflow of defecting products and avoiding the rejection of the entire packaging with important benefits in terms of quality and savings.

Harle2D can be standalone installed. Harle3D can be installed only in combination with Harle2D.

One solution combining 2D|3D controls

Production quality improved

Avoid the outflow of defective products

Inline efficient inspection

Single product rejection management

Developed with powerful proprietary algorithms, Harle2D|3D is designed to check 100% of oral solid dose products on filling & counting, blister thermoforming or strip packaging machines.

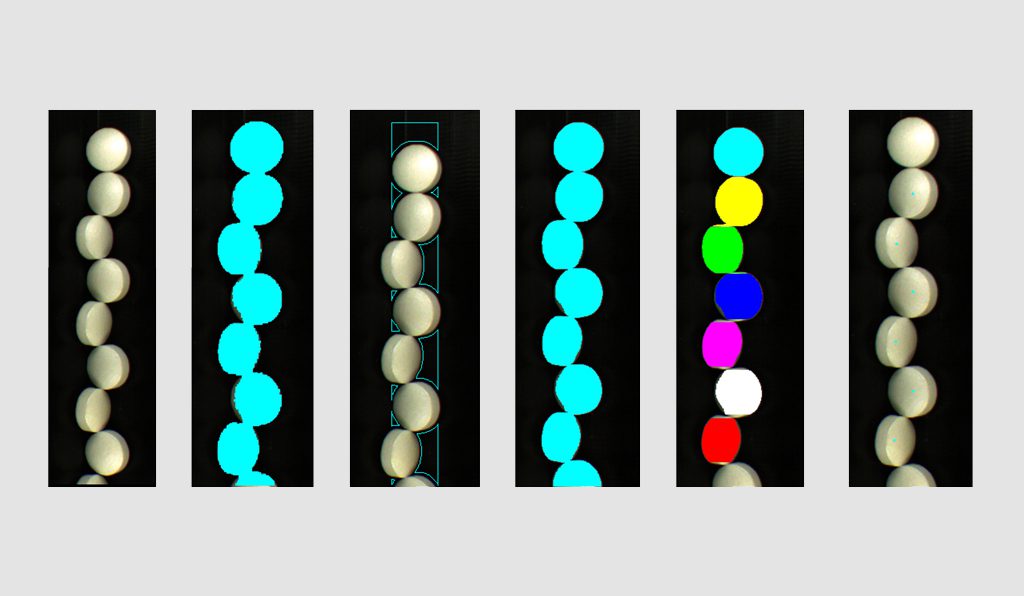

The 2D controls allows to check the traditional pictorial and geometric parameters of products, such as shape, size, color and presence of major defects of all tablets or capsules before the end of the feeding channel. The bi-dimensional check allows to control the products find all the defects on the top visible surface of the object.

The 3D technology completes the inspection, allowing to capture the whole product images, without blind spots: using a LED pattern projection method, Harle3D can control each product in its entirety, allowing the identification of defects as happens for decapped tablets.

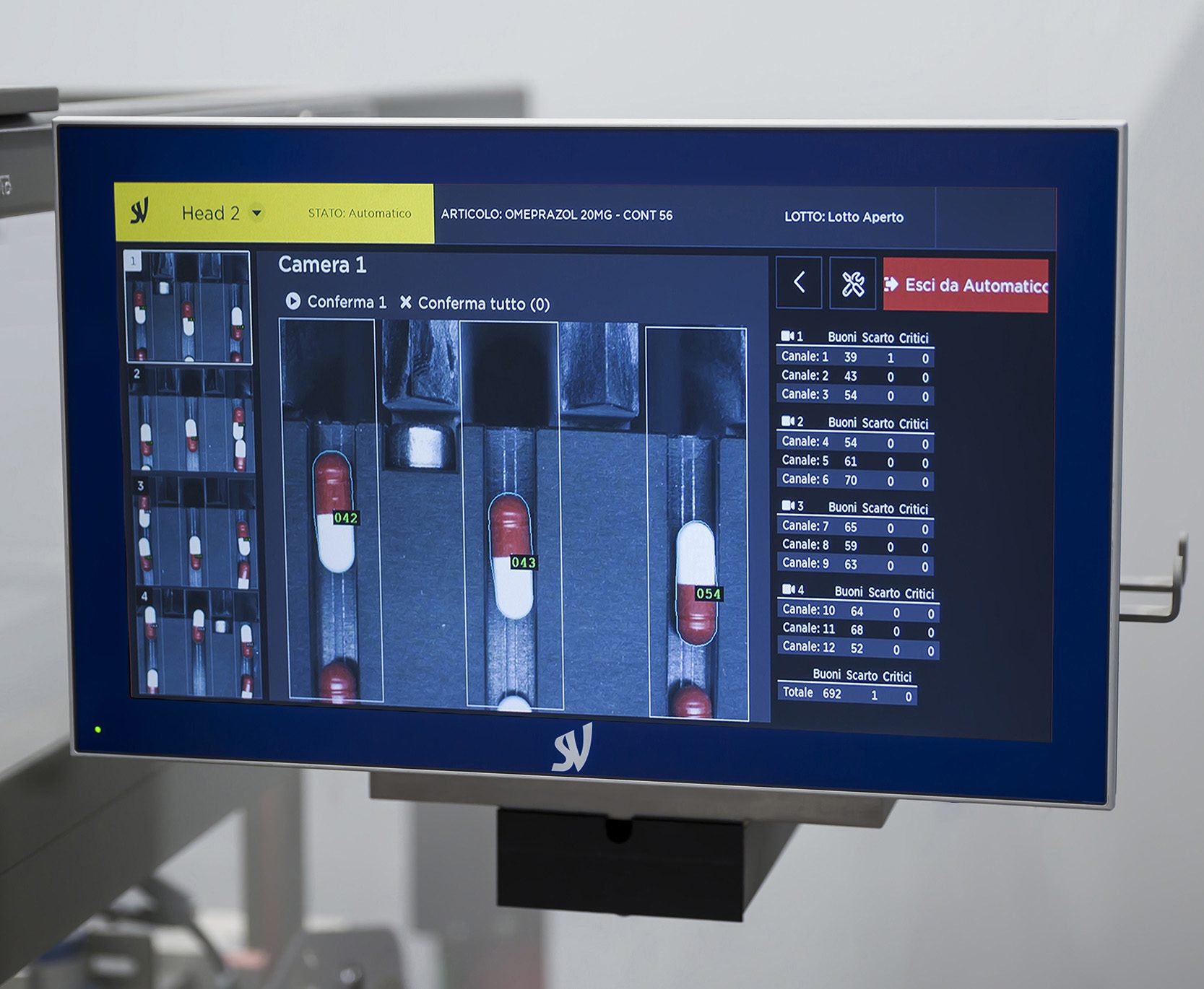

The HMI display shows in real-time the results of every product checked and, while 100% of products units are inspected, the vision inspection system manages the rejection of each non-compliant items.

The vision system can be installed on any filling and counting, blister or strip packaging machine currently available on the market, perfectly integrating itself thanks to its automation logic – thus without impact on the production speed.

Specifically designed for the pharmaceutical field, the system is entirely compliant with all industry regulations.

SEA Vision’s expertise in integration is built on decades of experience working alongside machine manufacturers to satisfy the needs of pharmaceutical customers worldwide.

Such experience guarantees correct machine integration, accurate signal exchange management, and integrated automation and rejection logic.

Harle2D|3D can be integrated on machines with different automation levels, from entirely automated or semi-automated to modules with a low automation level.

The graphical oscilloscope allows the observation of signal patterns and keeps them under control, facilitating the diagnostical operation.

The entire process is handled efficiently, from the control execution to the rejection of defective products.

Harle2D|3D is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.