The label verifier station automatically prints and eases the peeling of labels for cases and pallets, doing ANSI grading control in real-time thanks to the vision system with a dedicated camera and light unit that includes.

All the labels are automatically controlled and ready to be applied by the operator, for a safer process.

As an alternative, the labels can be printed at one time and rewinded on the reel for later use.

ANSI Grading control

Integrated vision system

Quick format change

User-friendly interface

Speed-up labeling operation

Labelverifier is a smart workstation that features a module with a roll holder device for label printing, inspection, and peeling functions.

Its simple and functional design makes it the perfect choice to speed up manual label application for small packaging batches.

Thanks to a specifically designed combination of optics and light units the workstation perform ANSI Grading control in real-time perfectly granting the correctness of all the label.

The software is able to print and inspect different label formats, in order to serve several packaging lines. Changing the format is very simple, without the need for any hardware modifications.

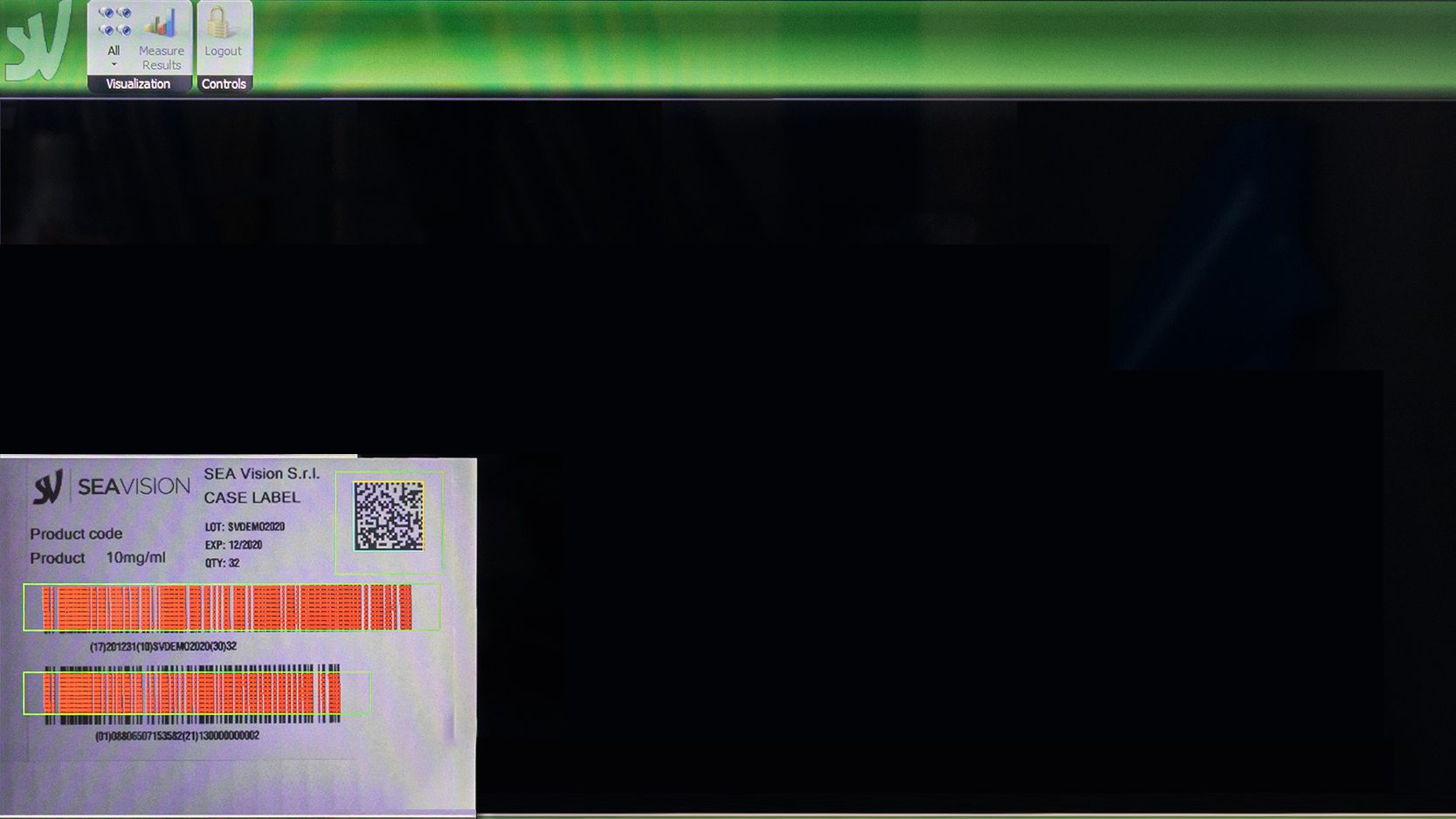

All the inspection results are visible in real-time on the HMI, where the display highlights possible issues to the operator such as errors, defects, or low ANSI Grading quality – to ensure an error-free production.

The workstation features a lightweight design. The reduced size allows it to be positioned everywhere even in small-sized pharmaceutical production environments.

The internal software is specifically designed for the pharmaceutical market, and it is compliant with the industry regulations, with user access regulated by FDA 21 CFR part 11 and annex 11. All events are registered by the software in an audit trail file to keep track of all the security-relevant activities.

The continuous Software development follows Gamp 5, to always improve products quality and consistency.

The workstation includes OCVmulti, a powerful vision system, completely developed in-house by SEA Vision. OCVmulti is capable to perform complete sets of inspections on pharmaceutical products and their packaging.

Thanks to powerful programmable measurement tools, no control is impossible for OCVmulti.

The latest generation systems of SEA Vision include a virtual PLC, in always more performant software. Logi-C is the new software tool developed by SEA Vision to program complex automation logic. The smart tool is useful to perform different automation processes, with the help of guided instructions. Logi-C works just like a traditional PLC, adding more power and configurability.

Labelverifier is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.