Countstation is the smart workstation to perform automatic syringes and cartridges counting in nest and automatically print nests and pallets labels with all the relevant batch information.

It is a useful solution to perform perfect product counting in case of manual operation performed on small batches, in case of internal products movement between the production and the warehouse, and to perform always a reliable control on the product quantity.

The pharmaceutical counting machine is equipped with a powerful vision system with a specifically designed camera and backlight unit to assure the best image acquisition from the top.

Eliminate counting errors

Save-time solution for increased production capability

Full or partial nest management

Portable all in one station to serve different lines

Automatic label printing for nests and pallet

Countstation is a portable pre-filled syringes and cartridges counting module designed for product counting in nests, with the aim to accelerate the time needed for these kinds of procedures whilst eliminating possible manual counting errors.

The system is flexible and can count any kind of pre-filled syringes and cartridges in nest.

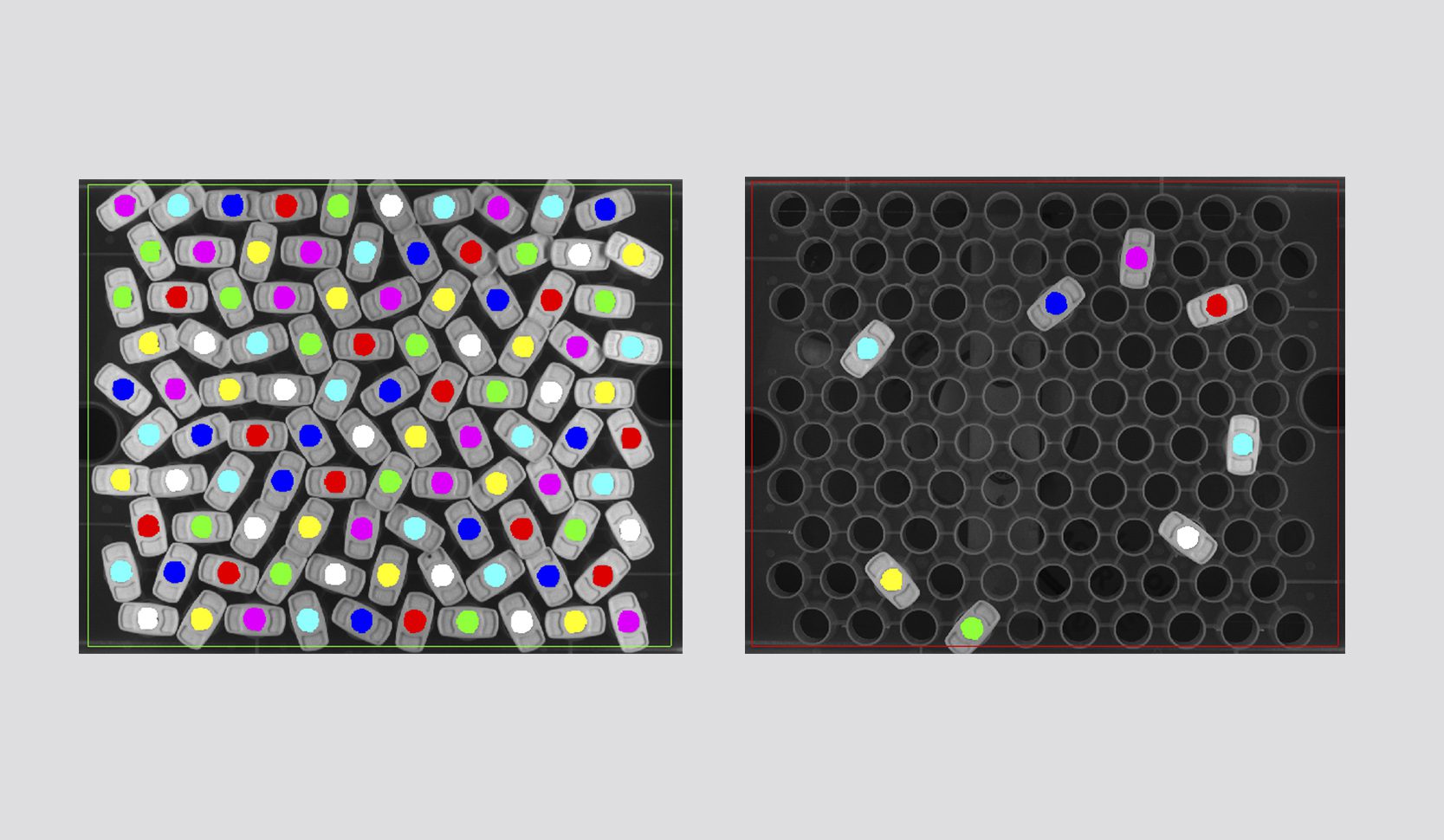

The operative workflow is simple. The operator places the nest to be checked under the inspection camera where the control happens.

The counting of products is performed by SEA Vision software that uses a geometrical multiple pattern-matching function (possible thanks to the Programmable Measure tool); this is done through the research of a learned model. The pattern could be the stopper, the body or any other part of the product depending on its geometrical shape and on the part exposed to the camera.

In case of incorrect nest detection (lower or higher number of syringes than the expected or empty nest) an error message is displayed on the screen together with the instruction that the operator must execute.

The system automatically prints the nest label with all the relevant batch information. Finally, when the preconfigured number of nests has been controlled, a second printer automatically prints the pallet label. The pallet label includes the total number of the products within all the nests to accelerate future products movements.

Countstation can manage the counting even in partially-filled nests, typically left over at the end of a batch.

This compact pharmaceutical counting machine can be placed everywhere very easily, to serve several different lines as required, and allows for an increased production capacity thanks to the time saved.

The vision system is specifically designed for the pharmaceutical market, and it is compliant with the industry regulations, with user access regulated by FDA 21 CFR part 11 and annex 11. All events are registered by the software in an audit trail file to keep track of all the security-relevant activities.

The continuous Software development follows Gamp 5, to always improve products quality and consistency.

The workstation includes OCVmulti, a powerful vision system, completely developed in-house by SEA Vision. OCVmulti is capable to perform complete sets of inspections on pharmaceutical products.

Thanks to powerful programmable measurement tools, no control is impossible for OCVmulti.

The latest generation systems of SEA Vision embrace a virtual PLC, in always more performant software. Logi-C is the new software tool developed by SEA Vision to program complex automation logic. The smart tool is useful to perform different automation processes, with the help of guided instructions. Logi-C works just like a traditional PLC, adding more power and configurability.

Countstation is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.