Reworkstation is a manual warehouse workstation to execute rework and shipping operations.

Integrated system

Warehouse reworking

Shipment operations

Serialized / aggregated batch reworking

Lightweight and compact

Reworkstation is the system developed by SEA Vision designed to deal more efficiently with reworking operations on serialized/aggregated batches after the production on the packaging line, post-packaging warehouse reworking, and shipment operations.

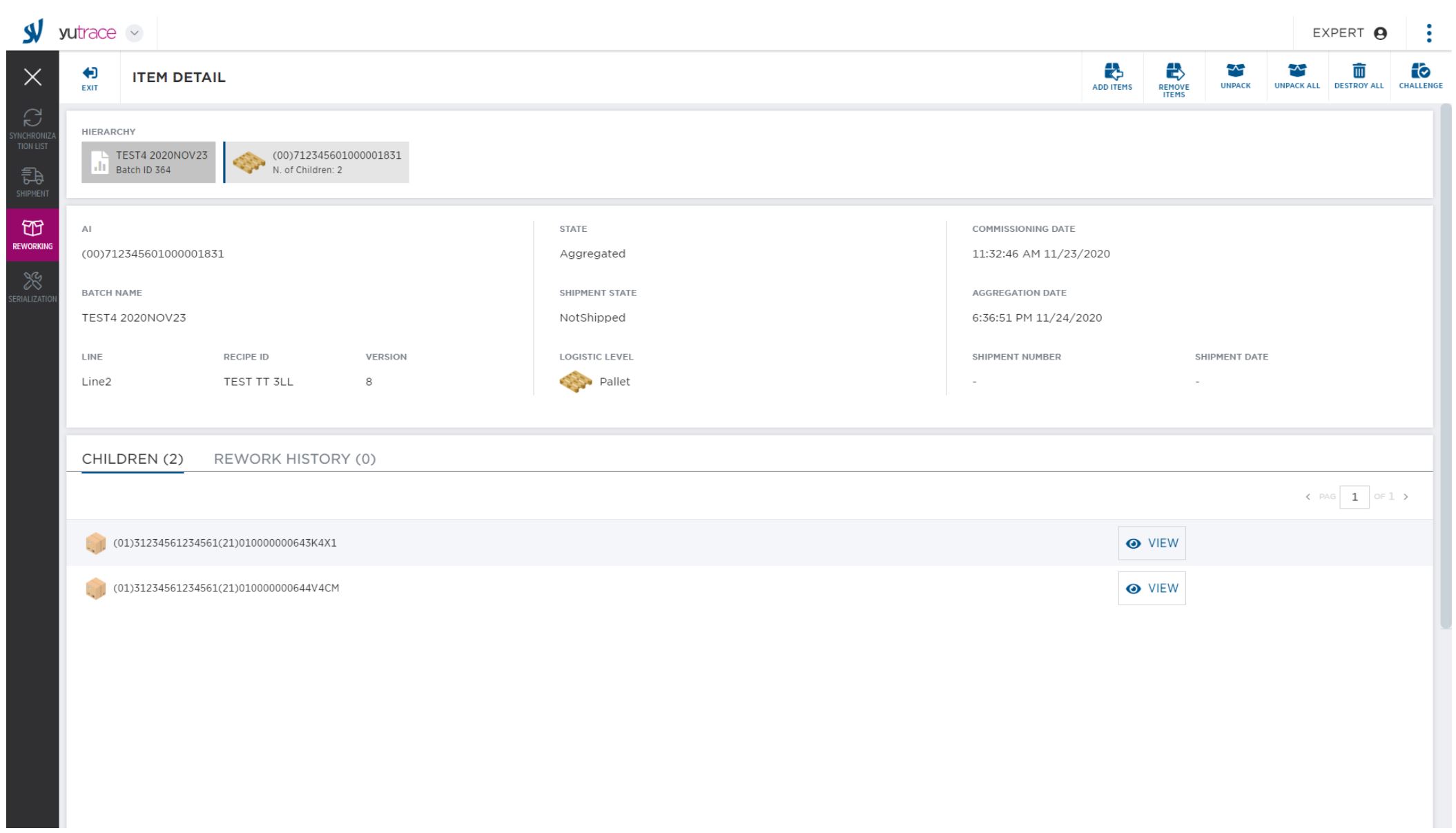

In case of post-production issues (eg packaging replacement, sampling, and others), the stand-alone unit allows: the manipulation of serialized and aggregated items to perform disaggregation operations, the decommissioning of items that need to be sampled/rejected, and the re-printing of serialized labels to reconciliate the aggregation relationship at the end of the process.

All the available information about serialization and the aggregation of hierarchical information are accurately displayed on the HMI.

In case of shipment instead, Reworkstation generates shipment files with all the necessary information of goods ready for shipment.

The workstation is equipped with a multi-plane scanner for an ergonomic and fast scanning of cartons codes; a slot to host a printer for cases and pallet labels reprinting: a compact, lightweight design to allow the positioning of the machine everywhere, even in small-sized pharmaceutical production environments.

The workstation features a lightweight design. The reduced size allows it to be positioned everywhere even in small-sized pharmaceutical production environments.

All actions perfomed by users on Reworkstation are saved in an Audit Trail file, to track all the security-relevant activities.

The internal software is specifically designed for the pharmaceutical market, and it is compliant with the industry regulations, with user access regulated by FDA 21 CFR part 11 and annex 11.

The continuous Software development follows Gamp 5 regulation, to always improve products quality and consistency.

Yutrace is the solution for the management of serialization process in the production site, capable of performing the provisioning of serials from Level 4 to line systems and performing reworking and reporting operations.

With an architecture that is specifically projected to adapt to the pharmaceutical industry’s logic, processes, and IT environments, yutrace prompts the evolution of the serialization environment into a source of 4.0 vision data intelligence.

Reworkstation is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.