SEA Vision is a worldwide top player in the aggregation and serialization field, for which it has been developing reliable solutions for over ten years.

The skills and experience of SEA Vision in inspection and serialization software architecture is a key point to manage all the aspects of such a challenging goal, to create a cutting-edge solution for any pharmaceutical manufacturer who wants to be ready for future regulatory implementations – and at the same time to gain an added value to their packaging processes.

Extremely reliable and accurate

Operations in real-time

End user and supply chain improved safety

Protects brands

GS1 standard compliant

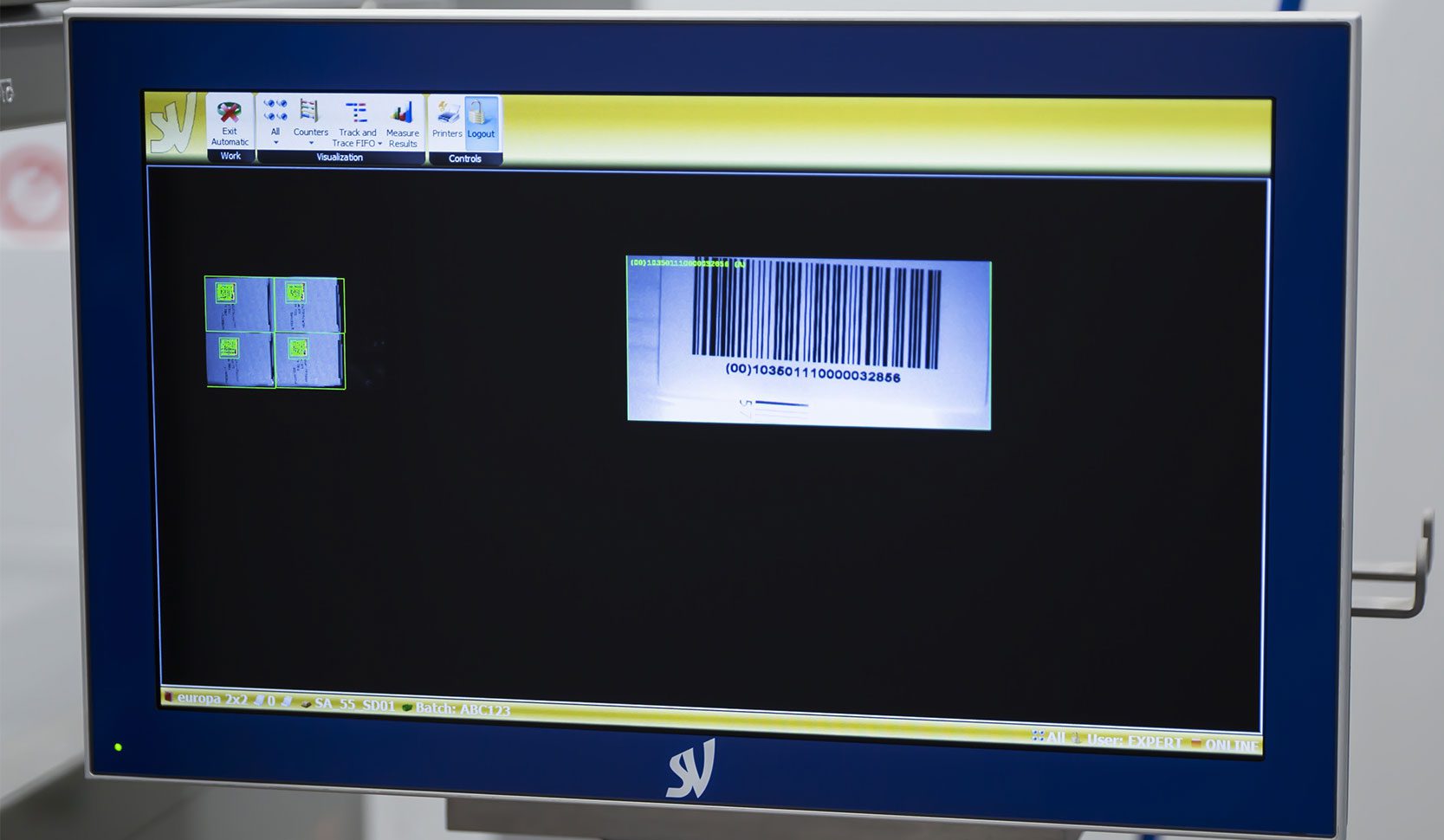

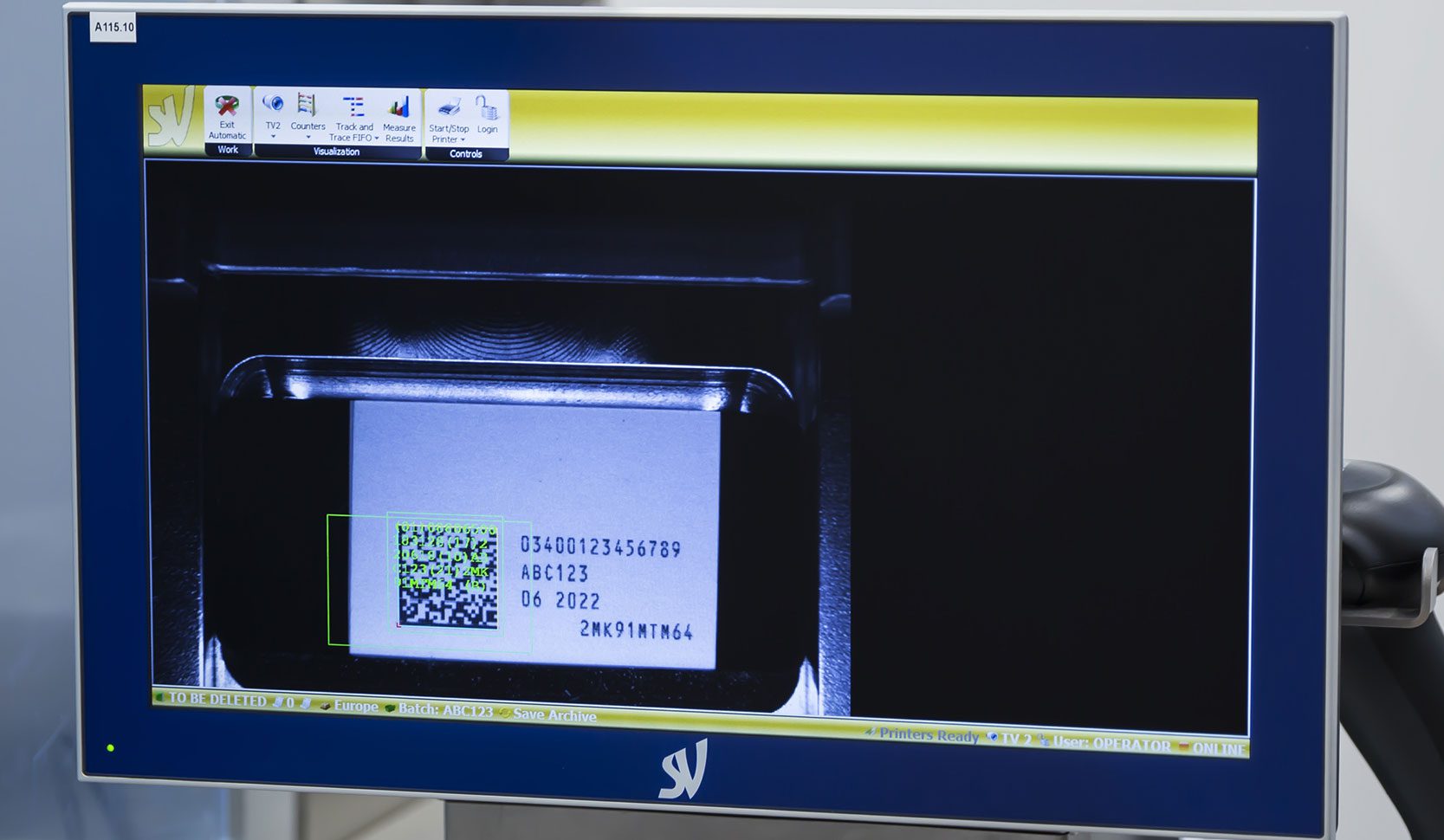

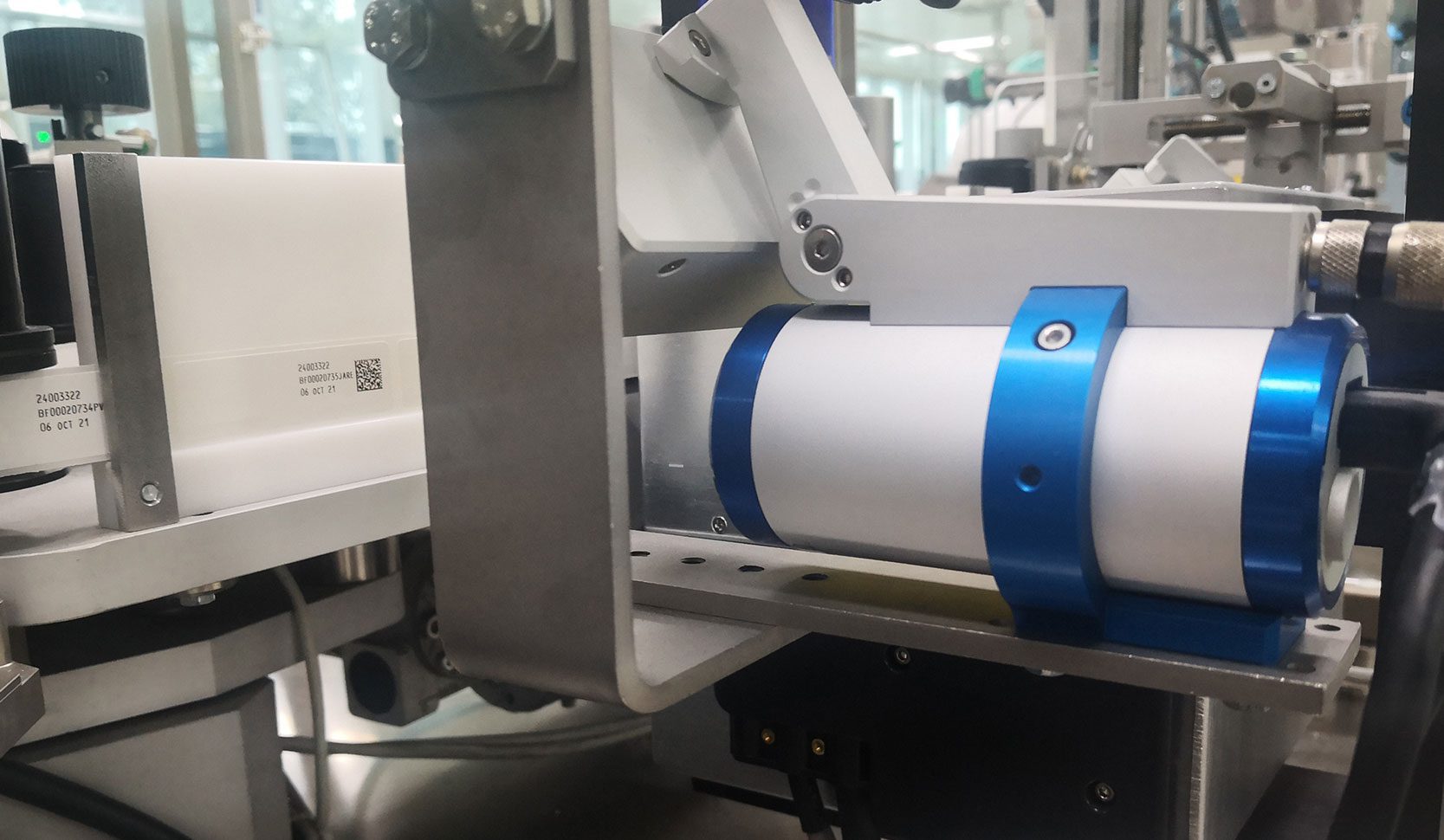

Developed by SEA Vision with proprietary algorithms, Tracker is the pharmaceutical serialization solution capable of performing runtime checks of serialized codes printed on serialized drug packages, and perform parent-child aggregation operations.

Concerning serialization, the software manages the in-line printing and inspection of variable data and serialized codes on cartons.The correct units (cartons, cases, and pallets) that pass the inspection are then commissioned, since Tracker communicates with yutrace (SEA Vision level 3 software) for serial numbers provisioning and posting operations.

Furthermore, the serialization system Tracker manages all the industrial devices installed on case packer and palletizers machines for the execution of aggregation operations between logistic units.

At the end of the serialization and aggregation processes, the communication with the level 3 system allows the subsequent notification to the level 4 platforms and Repositories.

Tracker support any type of aggregation and serialization: PoDA, PoDA+ or Track and Trace, in accordance with the relevant regulators in all markets worldwide. No matter what it is the automation level of the machine, the communication capability of Tracker with the PLCs of the machines through the exchange of digital I/O signals, allows a smooth and automatized rejection management.

Safe and reliable, this renowned serialization and aggregation system boasts many installations around the world on all the models of print and check, case packer and palletizer machines produced by all OEMs.

SEA Vision’s expertise in integration is built on decades of experience working alongside machine manufacturers to satisfy the needs of pharmaceutical customers worldwide. There are over 1500 serialization lines that use SEA Vision systems.

Such experience guarantees correct machine integration, accurate signal exchange management, and integrated automation and rejection logic.

Tracker can be integrated on machines with different automation levels, from entirely automated or semi-automated to modules with a low automation level.

The graphical oscilloscope allows the observation of signal patterns and keeps them under control, facilitating the diagnostical operation.

The entire process is handled efficiently, from the control execution to the rejection of defective products.

Tracker is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.