4.0 Pharma Software Suite > a-eye clearance_

Nowadays the pharmaceutical market requires more frequent changeovers on the packaging line with a high number of small productions. This increases the risk of a costly product recall for wrong products, labels and packaging entering in the lines. Furthermore, with smaller batches, the time dedicated to the line clearance

procedure raises and the efficiency of the process (OEE) is reduced.

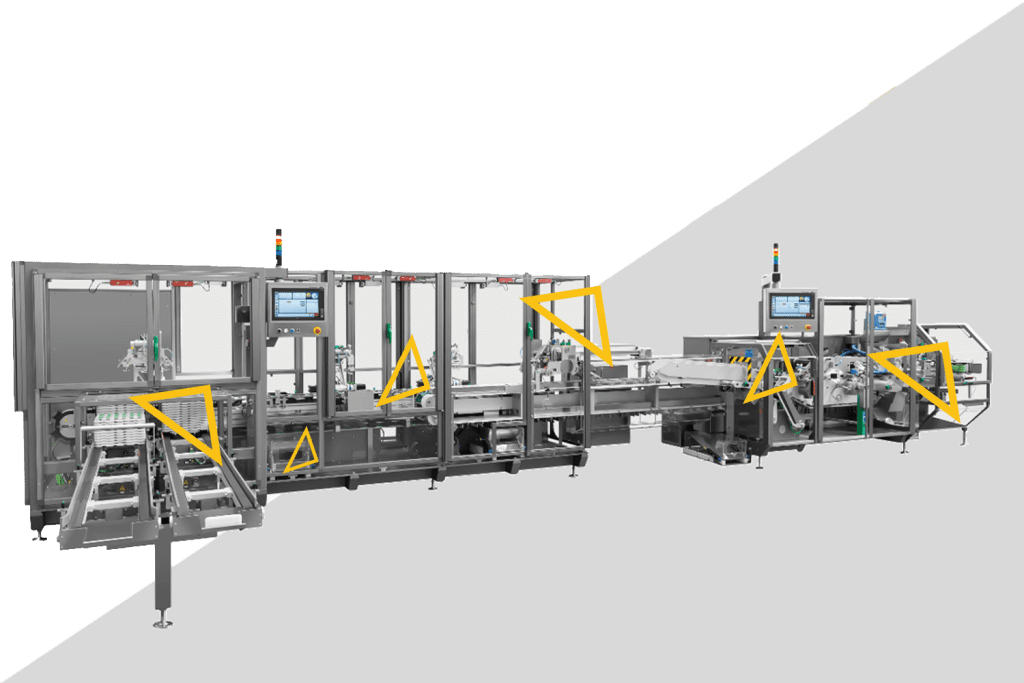

A-eye clearance is the new AI-powered automated technology for faster and more efficient processes of line clearance. A solution that combines software and hardware components to streamline the changeover times and improve the quality process of your packaging lines, passing from manual to paperless and automated line clearance processes.

A software designed to ease, and digitalize the line clearance procedures on packaging lines, before a batch or product changeover according to the customer’s SOPs.

Artificial Intelligence powered software

Advanced automation features

Evolve SOP in automated workflow

OEE improvement

Automated reports with process digital evidencE

This solution combines software and hardware components (cameras, sensors, scanners) that – once integrated into the line – allow to check in real-time the anomalies on each critical area detection point

The line clearance procedure usually includes three consecutive phases that a-eye clearance follows or manages accordingly to customers’ needs:

- Clearing all previous batch-related items

- Cleaning all the line parts

- The final automatic checking phase

Discover below what a-eye clearance system can do, for each of these phases.

With a-eye clearance the clearing and cleaning phases are executed by means of a step-by-step guided workflow based on the customer’s SOP.

A Smart document system describes the actions to be performed during the procedure showing to the operator the right instruction documents, pictures, or videos.

A-eye clearance system automatically performs the checking procedure, to verify that every checkpoint has been correctly cleared – giving immediate evidences of the control. In case of foreign object detection, the system immediately alerts the operator.

Real-time anomalies detection is always active and help operators in different ways, for example during the format change the system highlights the missing and misplaced components, helping the operator to don’t forget details.

QA automated reports

The system automatically collects information and digital evidence for every performed phase and action (both automatic and manual). At the end of the production batch, the data collected are used for the creation of automatic and personalized QA reports.

Go Paperless!

All the procedures are digitalized and the needed reports are automatically filled in digital formats.

This helps to reduce the quantity of paper travelling back and forth on the line, reduces the space needed for physical archives, and helps the environment.

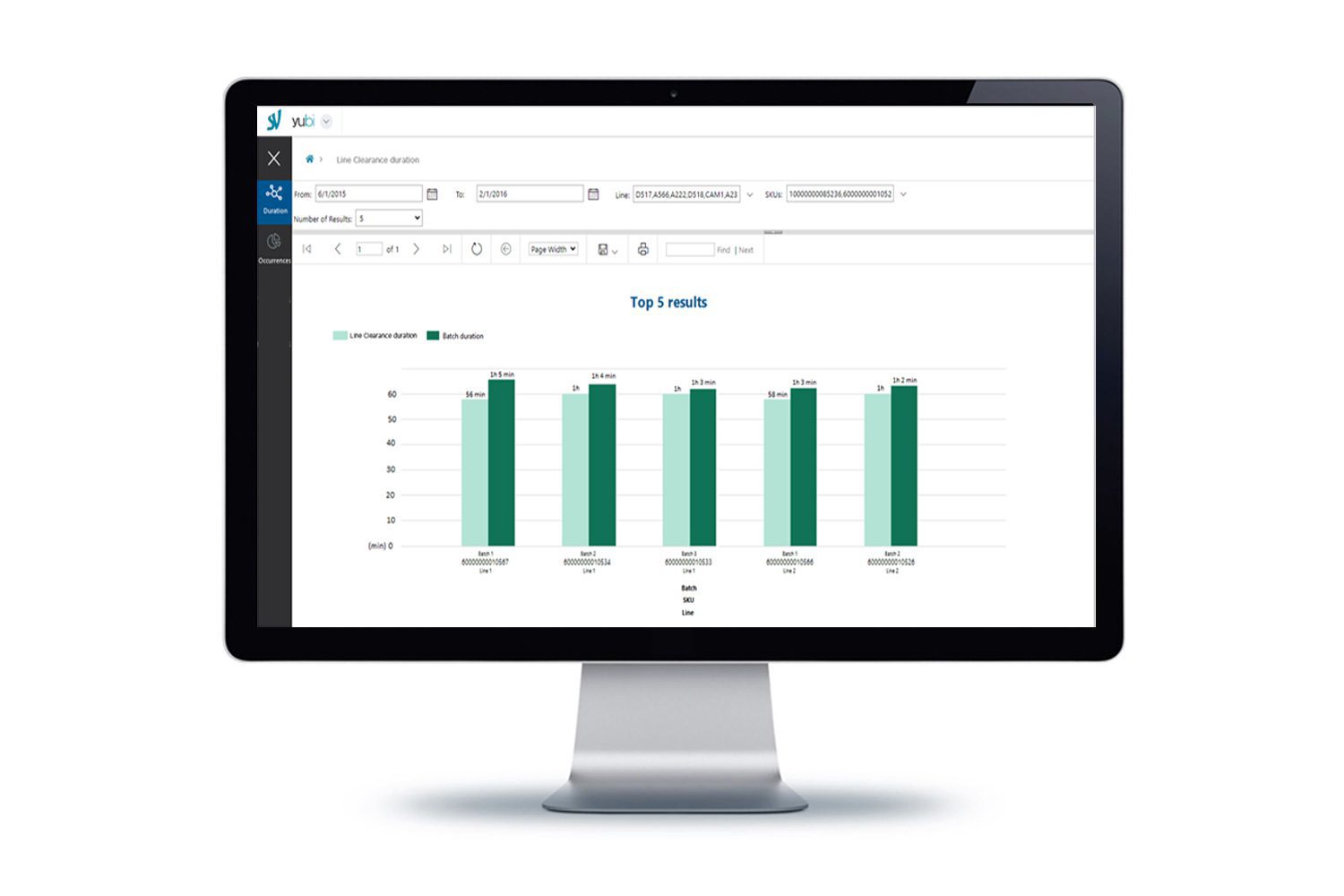

Business intelligence insights

A-eye clearance e is an extraordinary tool able to elaborate all the recorded data and to give you extra information/insights about your production line. It includes Business Intelligence tools that adds the possibility to smartly elaborate the huge amount of data collected and extract useful information to increase the performances further.

An example: changeover time of different line clearance processes can be deeply analysed in order to understand how to improve and reduce this time, increasing productivity.

↓ Click below to discover all the other features of YUDOO FOR DIGITAL QUALITY ↓

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.