Advanced Vision Systems in Cosmetics Manufacturing

The cosmetics industry is undergoing a remarkable transformation, driven by the integration of cutting-edge technologies. In a world where beauty standards are constantly evolving, the demand for flawless products has never been higher. To meet these expectations, cosmetics manufacturers are turning to advanced vision systems and artificial intelligence (AI) to revolutionize their production processes.

In this white paper, we delve into the insights shared in a recent episode of the Cosmofactory Podcast, hosted by Deanna Utroske – and produced by Cosmoprof Worldwide Bologna.

The episode features Francesco Ringressi, Cosmetic Business Development Manager at SEA Vision, a leader in the implementation of AI-driven vision systems. This conversation sheds light on how these innovations are enhancing quality control, boosting efficiency, and paving the way for a new era in cosmetics manufacturing.

Through detailed case studies, we explore how SEA Vision’s technology is transforming the inspection and production of cosmetics. Join us as we uncover the transformative power of these technologies and their potential to set new standards in the beauty industry.

To discover the cosmetic inspection and traceability solutions that SEA Vision offers, visit the page: https://seavision-group.com/cosmetics-solutions/

Background

Artificial intelligence (AI) and vision systems have revolutionized various industries by enhancing quality control and efficiency. In cosmetics manufacturing, these technologies are becoming increasingly crucial to ensure product quality and streamline production processes. Manual inspection methods, while traditional, are often labor-intensive and susceptible to errors, demanding a necessary shift towards automated solutions.

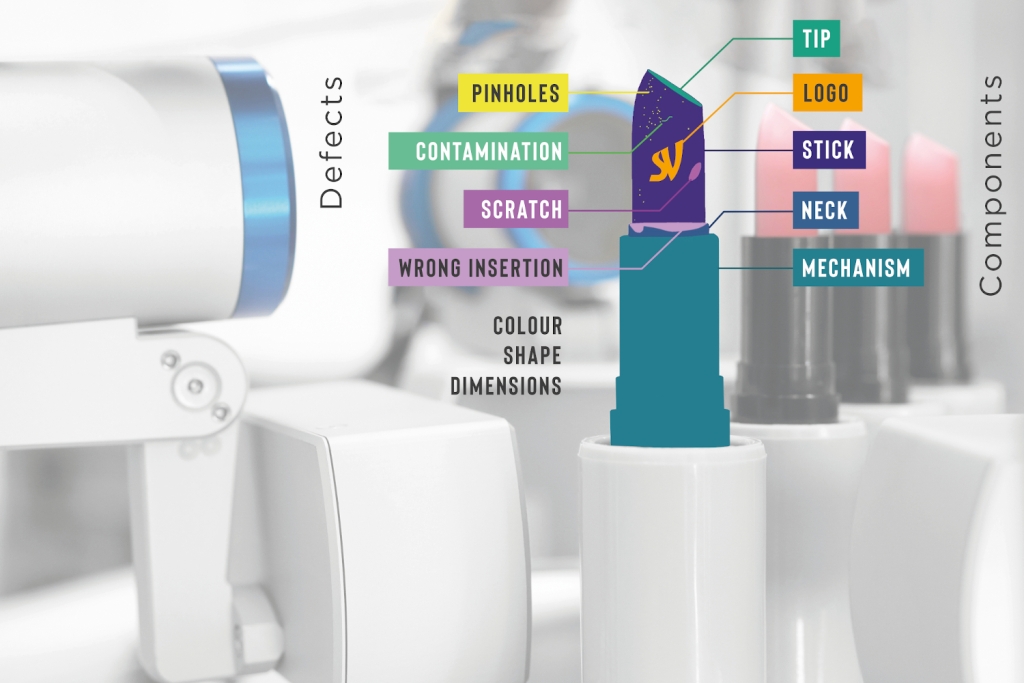

Case Study 1: Lipstick Inspection System

Problem/Challenge: Manual inspection of lipsticks is a labor-intensive process that places a significant strain on workers. They must spend long hours inspecting each product for tiny defects, such as surface imperfections, color inconsistencies, or misalignments. This repetitive and monotonous task can lead to fatigue, which in turn increases the likelihood of human error.

This results in inconsistent inspection outcomes, where defects may be overlooked or misjudged. Human error in manual inspections can lead to variations in quality control, with some products passing through with defects, potentially affecting customer satisfaction and leading to costly returns or brand damage.

Solution: SEA Vision developed an AI-powered lipstick inspection system, a-eye lipstick (on this page you can download the catalogue). This system incorporates AI technology, utilizing multiple cameras to replicate, and even surpass, the human eye’s capabilities in defect detection.

Training the system involved creating a vast dataset of images, including real lipsticks. This data enabled the neural network to learn and accurately identify defects such as holes, color variations, and misalignments.

Results:

- The AI system demonstrated superior accuracy and consistency in quality control.

- It reduced human error and increased the efficiency of the inspection process.

- The system allowed for higher inspection speeds, alleviating production bottlenecks

Results:

- Improved traceability and transparency throughout the production process.

- Enhanced ability to identify and troubleshoot production errors.

- Contribution to sustainability efforts by reducing waste and improving resource utilization.

Case Study 2: Broader Applications of Vision Systems

Problem/Challenge: The cosmetics industry requires comprehensive quality control across a variety of products, each with unique inspection needs.

Solution: SEA Vision’s technology extends beyond lipstick inspection. The vision systems can be adapted for various products and manufacturing processes, ensuring proper labeling, packaging inspection, and production data tracking.

By integrating with other manufacturing technologies and collaborating with industry operators, SEA Vision tailors its systems to meet specific needs, enhancing overall production efficiency.

Common Themes: AI technology significantly improves accuracy and efficiency in manufacturing processes.

Success Factors:

- Collaboration with industry experts to tailor solutions.

- Adaptability of the technology to various products and processes.

- Comprehensive training data for accurate system learning.

Lessons learned

Continuous innovation is essential to stay ahead in manufacturing. AI holds the potential to transform traditional processes, making them more efficient and reliable.

Conclusion

AI and vision systems are pivotal in advancing quality control and efficiency in the cosmetics industry. The case studies from SEA Vision illustrate the transformative impact of these technologies, highlighting the importance of adopting advanced solutions. As AI continues to evolve, its broader adoption in manufacturing is expected to bring even greater benefits, paving the way for a more efficient and sustainable future.