The production phases management and execution solution provided by yudoo, allows to manage all the production processes, guiding the operators and keeping track of all the activities; the system records the duration of every operation and collects important information for KPI analysis purposes.

Workflow configurability

Faster and safer operation with guided instructions

Reduction of mistakes caused by human errors

Phases times tracking

KPI analysis from collected information

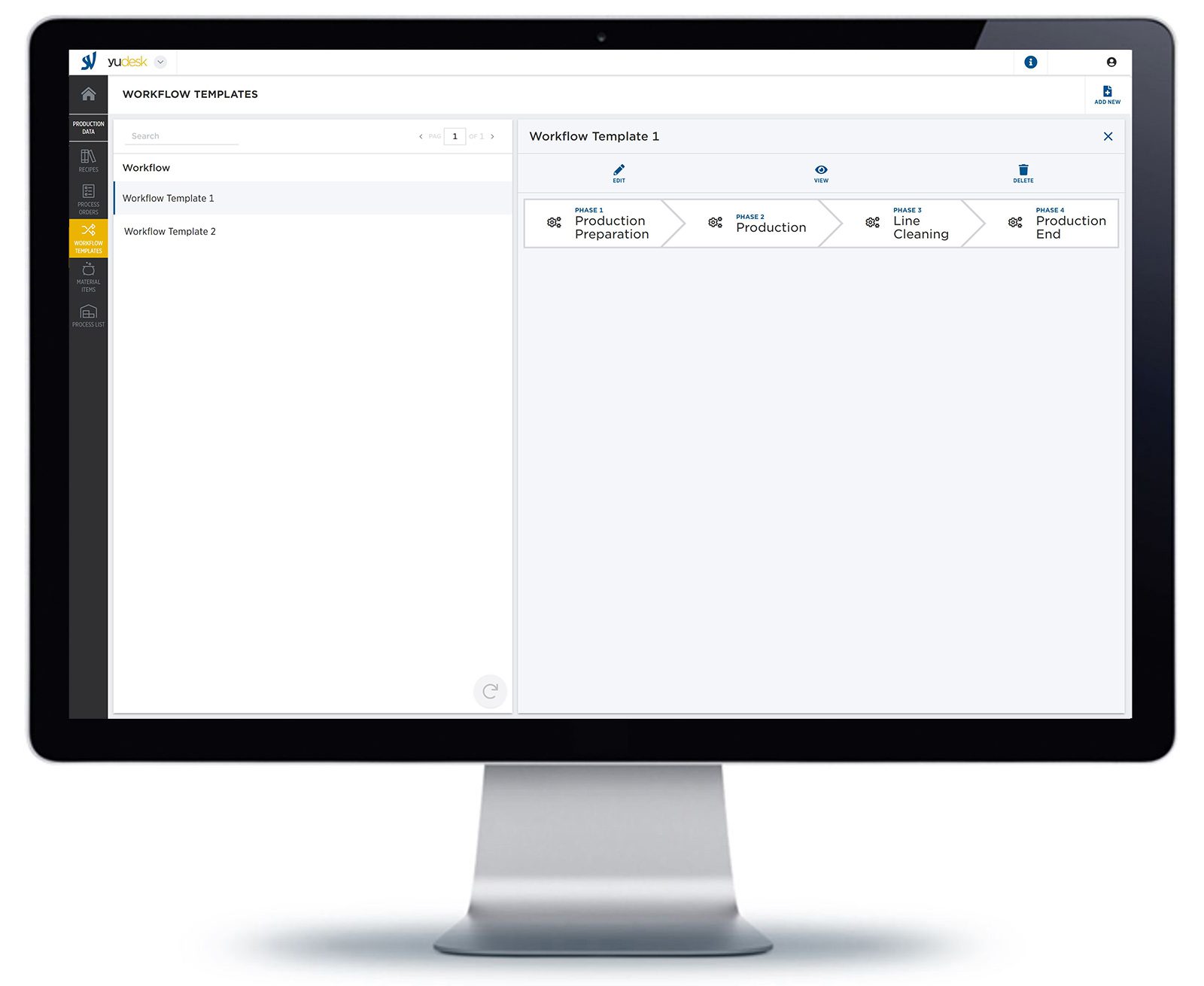

Yudoo translates every production process, even the more complex one, in a clear workflow. Each workflow is fully configurable and can include also the pre/after production phases (for example line preparation, line clearance procedures, and more). At this time, yudoo guide the operator with clear video instructions to carry out all the necessary tasks until completion. The whole production process is recorded, to collect useful data for business intelligence analysis.

Workflows:

- Split the whole production process into phases

- Track the duration of each phase

- Highlight inefficiencies in the process and help to take corrective actions

- Collect all the information useful to be analyzed and compared into different processes

- Include one or more tasks of each workflow step

Tasks:

- Guide the operator in all the activities

- Build a detailed log of all the activities

Features and compliance

The production management system is specifically designed for the pharmaceutical market, and it is compliant with the industry regulations, with user access regulated by FDA 21 CFR part 11 and annex 11. All events are registered by the software in an audit trail file to keep track of all the security-relevant activities.

The continuous Software development follows Gamp 5, to always improve products quality and consistency.

↓ Click below to discover all the other features of YUDOO FOR DIGITAL AUTOMATION ↓

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.