A pharmaceutical digital hub with a straightforward user-friendly interface for the centralized management of production environments: yudoo is the pharmaceutical software suite of SEA Vision that brings the digital transformation to reality.

Yudoo connects and collects data from IT and OT systems: all the enterprise systems (ERP, MES,…), track and trace and vision systems, machines and external services (for example vacuum and heating systems…) become integrated sources of data for real-time operations and business intelligence analysis. The data acquisition on all the latest-generation machines that use open communication protocols (OPC-DA, OPC-UA, MQTT, Modbus, and others) is performed by yudoo automatically. Otherwise, in case of older equipment and packaging machines, an IoT Kit is provided to make the data collection possible.

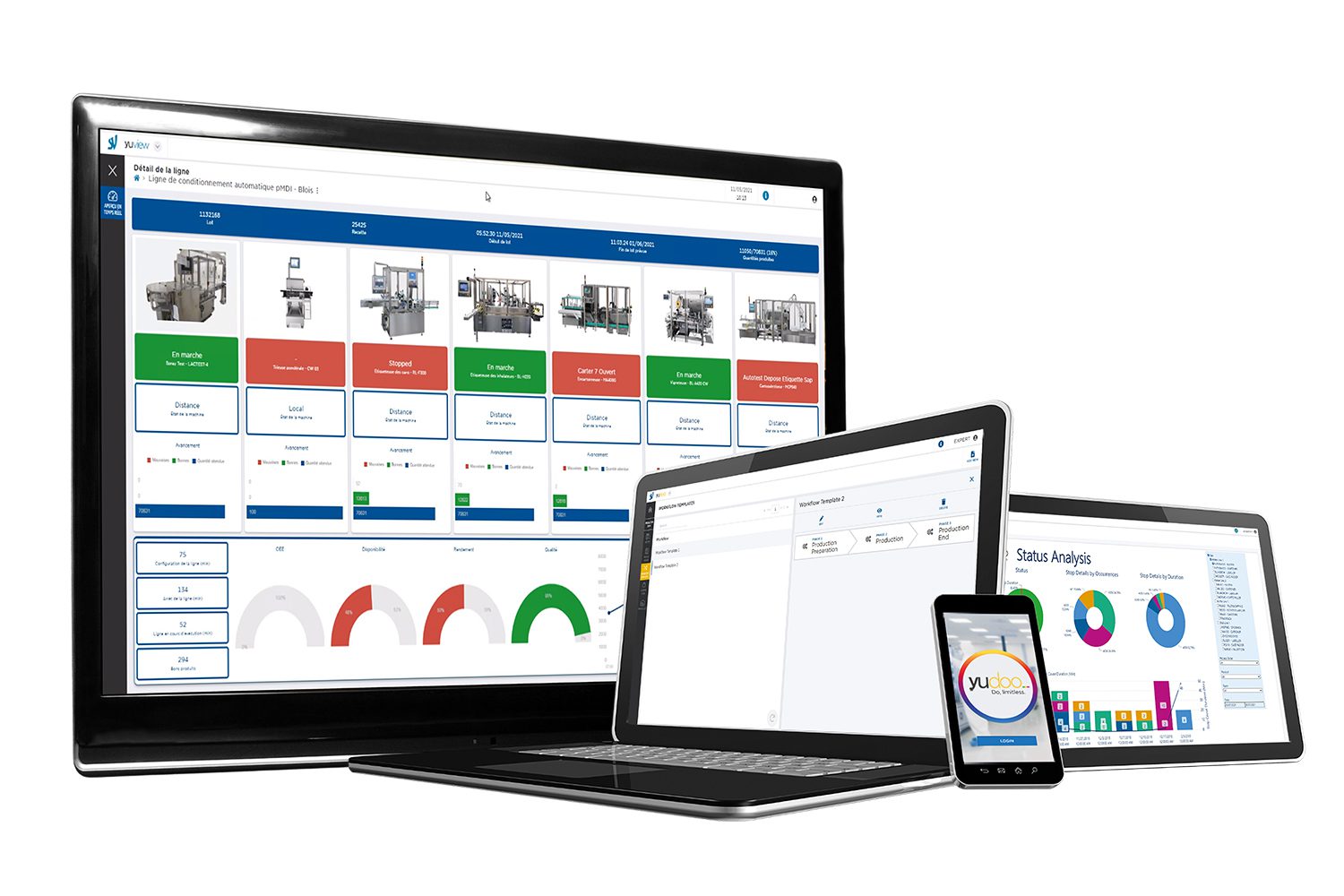

The web-based user interface can be used from any device and is designed to reshape the concepts of Paperless Manufacturing, OEE, Big Data Analysis.

An extraordinary opportunity of taking your manufacturing environment toward industry 4.0.

Yudoo architecture is designed to be modular and scalable depending on the different business needs.

In its complete version, yudoo includes functionalities for managing production lines, integrating the existing Track and Trace architecture for serialization management, real-time OEE performance analysis, and evolved KPIs based on Business Intelligence tools.

Explore the solutions that yudoo offers and choose what you need.

A complete toolset to manage all pharmaceutical production quality requirements. What’s the goal? To digitalize qualified documentation in total compliance with Standard Operating Procedures and existing regulations.

Paper

On Glass

A modular solution for the digitalization of paper-based production procedures.

Line Clearance Automation

Artificial Intelligence powered solution to automate line clearance processes.

QA

Reporting

Customizable reporting tool to extract all the internal quality procedures parameters.

Batch Release

Analytic Tool

An advanced quality analytical tool to boost batch release times.

.

Through yudoo, all the machines involved in the production process are centralized and very well managed: all the phases and actions appear as clear workflows. An error-free interface guides operators throughout their daily activities creating a new automated routine. As control increases, time and costs are cut.

Advanced Production Phase Management And Execution

Configurable automated workflow.

.

Multistep Process Order

Manages multiple-step process orders, in one or more production lines.

.

Asset

Management

Well-structured hierarchy that defines all the sources of information.

.

Realtime Shopfloor Dashboard

Production dashboard that displays shopfloor data in real time.

.

Advanced Work Shift Scheduling

Work shift definition and templating to suits any production needs.

.

Manual Event

Input

Manual justification of idle events and manual shutdowns to increase report quality.

Yudoo reveals hidden equipment inefficiencies and suggests the best solutions to enhance production. Data collection and real-time performance calculations help you to make better business decisions. The historical data collected ensure advanced analysis and insights.

Overall Equipment Effectiveness

OEE automated calculation with results displayed on dashboards in real-time.

Advanced KPIs and Reporting

Beyond OEE, efficiency calculation extended to special parameters.

Data Historian

Fast and secure historical data collection storage.

.

Business Intelligence

Analytic tool with customized reporting.

.

Yudoo provides all the tools to manage track and trace configuration, execution, reworking operations, and monitoring. Thanks to the business intelligence tool applied to track and trace, the efficiency of your serialized production lines is always maximized and under control. Your brand is fully protected.

Corporate

Solution

Level 4

.

Level 4 software solution. Contact point between corporate level and Level 5 of National Regulatory Agencies.

Master Data Configuration,

S/N Provisioning & Posting

Level 3 software solution. Allows communication between level 4 and the vision systems installed on the lines.

Reworking,

Shipping,

Warehouse

Operations

Reworking and shipment functionalities supplied in a workstation or mobile solution.

Track

&

Trace

Monitoring

Real time dashboards, business intelligence dashboards and insights for track and trace.

Centralized

Multi-line

Pallet

Management

Complete software solution for centralized multi-lines palletizing systems.

.

Cosmetic

Traceability

.

.

Solutions for fighting counterfeiting along the cosmetic products’ supply chain.

.

All SEA Vision systems are integrated with yudoo with Input/Output data transfer. Vision system interfaces are reachable from yudoo and have the same graphic design so that critical information is easy to read.

The web-based user interface (WUI) of yudoo is accessible everywhere through secure access on every web browser. It is compatible with a wide range of industrial devices such as PCs, monitors, tablets, and smartphones. This allows great flexibility of use, for example.

PCs and notebooks:

- configuration

- execution

- supervision features

Wide monitors, maximize the visibility for the operator:

- show real-time dashboards on the production lines

- if placed outside the clean rooms allows the visibility of the shopfloor

Tablets, maximize portability features and:

- help to introduce paperless systems easily

- allow to start the batches and to follow the workflow procedures directly on the production line

Smartphones, maximize the supervisor user:

- allow notifications in real-time and helps to keep everything under control

Yudoo can interface with all types of existing machinery in the production context, regardless of digital data exposure capacity level thanks to an IoT Kit consisting of a range of sensors, hardware devices and an IoT Gateway.

Whether you have the latest generation machines or machines with limited digital data display capacity, we have the solution for you.